Food Safety

NPC’s and CFP’s state-of-the-art food processing facility is poised for a long future in protein processing. The temperature-controlled storage and processing space was designed to comply with the Global Food Safety Initiative’s standards, which specify, sloping floors for proper drainage, state-of the art drains that are thoroughly cleanable, and wall-to-floor interfaces that facilitate proper sanitation.

NPC and CFP are committed to safeguarding the products that are delivered to the public. We embrace the science based HACCP approach to food safety in all stages of meat production and preparation processes, including packaging and distribution. The meat we process is regulated by the USDA; however, we go beyond the regulations to achieve the safest products possible. All of our suppliers are required by NPC and CFP to undergo third party audits. In addition, we use an outside firm to audit our facility for GMP and Food Safety Systems on an annual basis. An additional audit is conducted yearly to verify that our process controls are effectively reducing the likelihood of E. Coli contamination.

NPC & CFP operate under a Quality Assurance Program and a fully implemented HACCP plan, with all appropriate critical control points identified and adhered to.

All products produced by NPC & CFP are subjected to screening by state-of-the-art metal detection technology, for added assurance that the physical contamination control program employed by NPC & CFP is effective.

NPC & CFP guarantee the quality of the products it produces. We guarantee that all of our products are free from adulteration, as defined by the Federal Food, Drug and Cosmetic Act (United States Code, Title 21, Chapter 9; Section 342).

Primal cuts of meat are treated with Enviroguard® MP-2

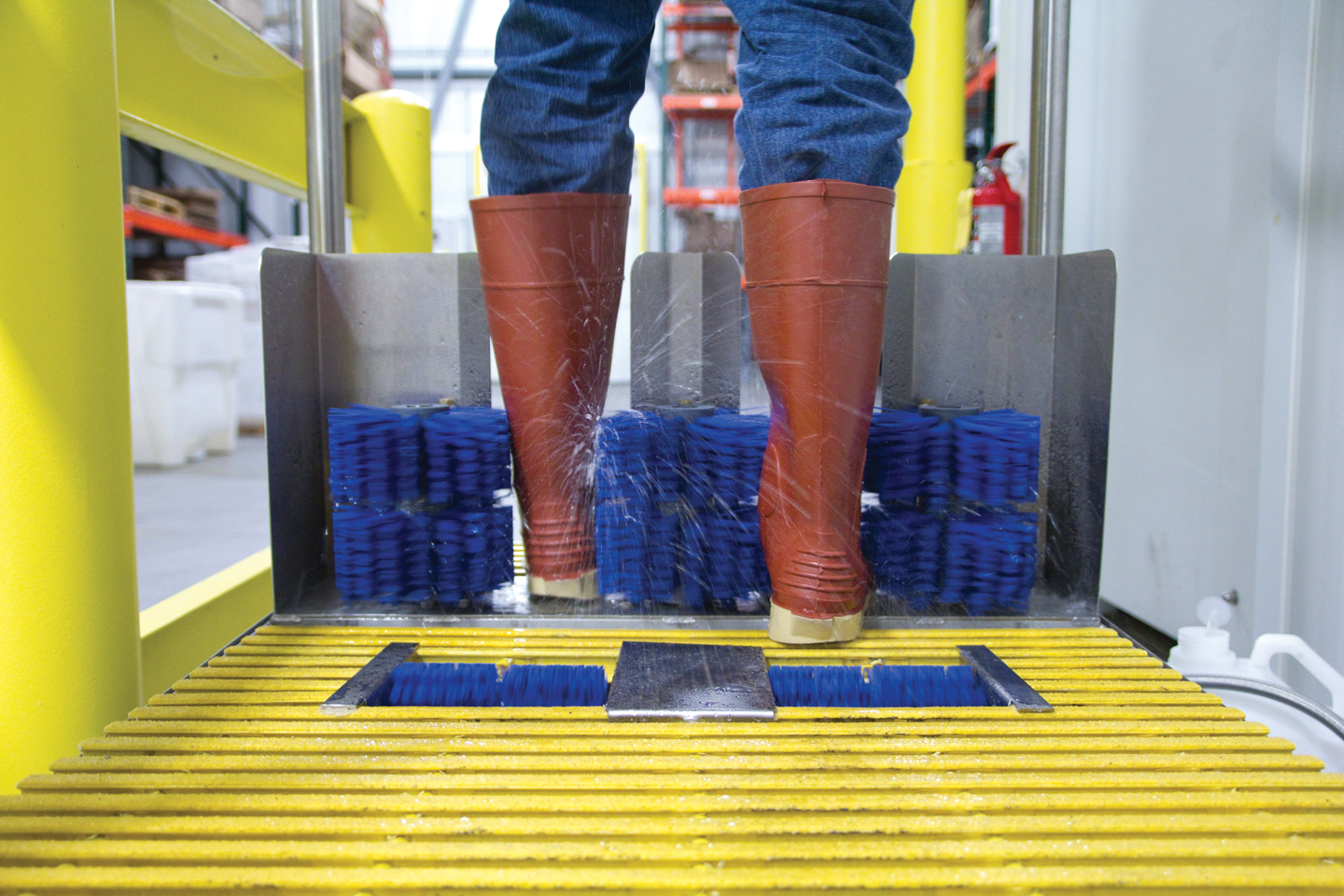

NPC’s & CFP’s employees are committed to a comprehensive sanitation program. They receive a complete outfit of sanitary clothing daily. They must remove all jewelry, walk through a sanitizing foot foam, and wash their hands with an approved E2 hand soap.

NPC’s & CFP’s docks, coolers, freezers, and production rooms are monitored 24/7, and kept at temperatures well below critical limits in order to extend the shelf-life of raw materials and finished products. Deviations in set-point temperatures are responded to immediately.